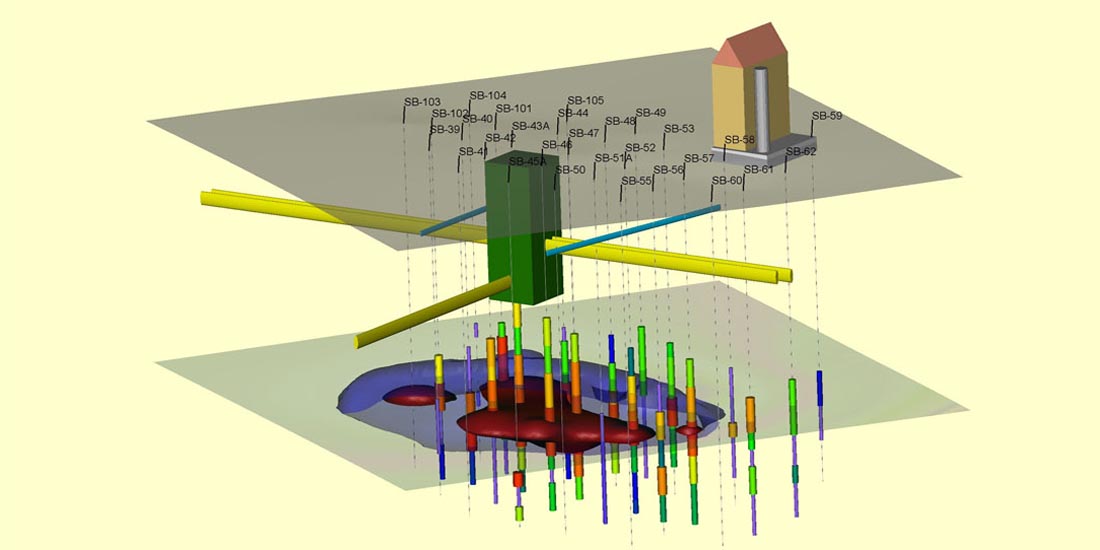

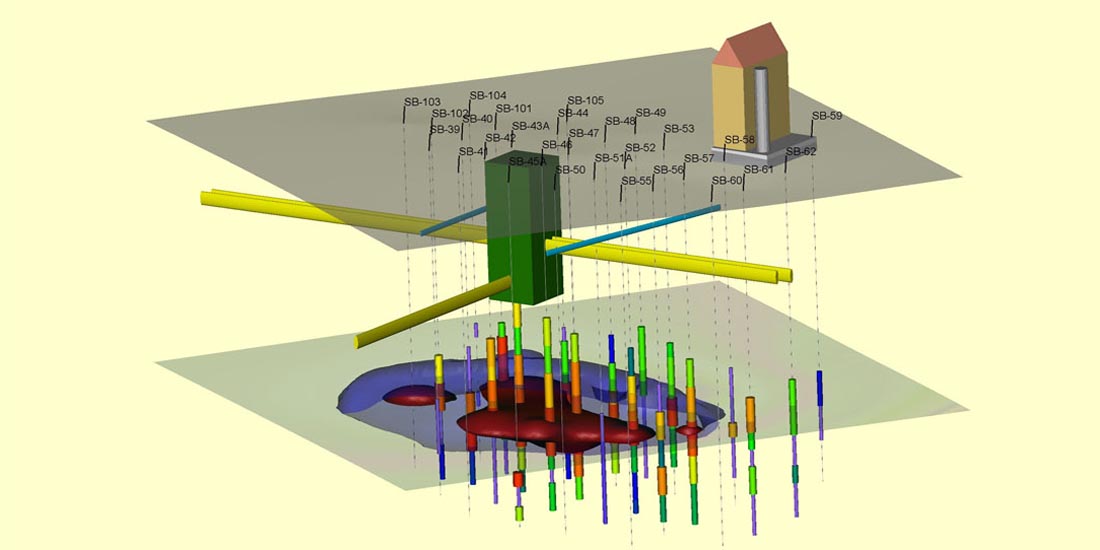

Visualizing JP-8/jet fuel release

Pease Air National Guard base/release from fuel vault #4

Portsmouth, New Hampshire

Challenge

An estimated 9,000 gallon release of JP-8/jet fuel occurred in a buried fuel line vault at

the Pease Air National Guard base in Portsmouth, New Hampshire. A faulty valve seal

was determined to be the cause of the release, and immediate response actions

included soil excavation around the vault and installation of a temporary light non-

aqueous phase liquid (LNAPL) recovery well. However, the need to maintain active

fueling operations precluded removal of the vault and the impacted soil immediately

below the vault. An estimated 6,000 gallons of JP-8 remained in-situ.

Air sparging with soil vapor extraction was implemented next in an effort to reduce the

residual mass of JP-9 beneath the vault. System operation was carefully documented to

demonstrate continued LNAPL mass removal. The New Hampshire Department of

Environmental Services (NHDES) requested an analysis of remaining JP-8 at the site,

and SES was retained to delineate the 3-dimensional extent of the plume and calculate

total and potentially recoverable LNAPL at the site. Using simple direct-push drilling

combined with field Ultraviolet Fluorescence (UVF) screening, SES fully delineated the

LNAPL Plume in four days.

Using advanced physical laboratory testing SES was able to demonstrate that LNAPL at

the site was not mobile, and not recoverable in meaningful quantities. SES

recommended terminating active remediation at the site, resulting in substantial

operation savings. 3D visualizations, especially sharable 3D PDF models allowed

project stakeholders to understand the site in ways they previously could not

SES Value Added

- SES directed a field Ultraviolet Fluorescence (UVF) assessment to develop

complete 3D delineation of JP-8 plume beneath fuel line vault

- Collected frozen core samples for residual saturation testing by centrifuge and

water drive methods

- Developed a first of its kind correlation between physical, analytical and field

screening methods to verify efficacy of all methods.

- 3D Visualization with Surfer, Voxler and TurboCAD

- Created 3D PDF file of completed model for stakeholder sharing

- Total and potentially recoverable LNAPL volume estimates

- Presented results and recommendation to client and NHDES

- Recommended site closure to client and regulatory agency

- NHDES agreed that further remediation was no needed

Client